| The availability of high-quality single crystals is a prerequisite for in-depth investigations of new materials.

This is particularly true for the study of anisotropies in non-cubic compounds as well as for low-temperature investigations where

grain boundaries may cover the intrinsic behavior.

We prepare single crystals using different techniques:

- floating zone technique with 4-mirror optical heating: Often use of crucibles is impossible because of a reaction of the melt and the

crucible material. In the crucibleless floating zone technique the molten zone keeps together by capillary forces.

The optical heating is the optimal way to bring a narrow zone of the sample to melting.

The maximal lamp power of the furnace is 6 kW.

- Czochralski growth in Tri-arc- and Tetra-arc furnace:

The 25 kW furnace manufactured by Centorr enables Czochralski growth in inert atmosphere. Cooling of the pulling rod is based on the “heat pipe” principle.

- flux growth: For incongruently melting, refractory or evaporating compounds the flux growth technique may be used which makes possible growth at lower

temperatures. Flux growth is feasible in the mirror furnace as well (traveling heater method). For successful application of this technique knowledge

of the T-x phase diagrams is important. Phase diagrams are studied by DTA/TGA and HTXRD.

At present we focus on the growth of intermetallic compounds

with cage structure and/or unconventional behavior such as quantum critical behavior, Kondo insulating behavior, unconventional superconductivity. |

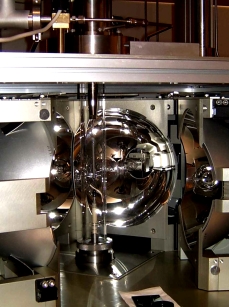

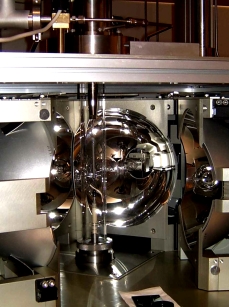

4-mirror furnace from CSC

The furnace is equipped with 4 halogen lamps and can be operated at pressures up to 10 bar.

|