Thin films

|

Thin films and coatings allow the intentional modification of surface

properties such as optical appearance, tribological performance, durability and

corrosion resistance. Thin film technology is also well established in the

areas of microelectronics, sensorics and magnetic storage media.

The Institute of Solid State Physics offers several Physical Vapor Deposition (PVD) methods for the production of metallic, semi-conducting and insulating films. They include thermal evaporation as well as reactive and non-reactive planar and post magnetron sputtering. In addition to the broad available spectrum of materials which can be realized by operating the above processes either in single or multi-source mode, the variation of process parameters allows the realization of a wide range of material structures. To characterize the deposited films the following methods are available: Scanning Force Microscopy and Scanning Electron Microscopy for the evaluation of the film morphology, chemical analytics by Electron Beam Microprobe and the determination of mechanical properties by micro-indentation and by adhesion testing. An intensive collaboration with other groups of the Vienna University of Technology broadens the scope of characterization methods by including e.g. Secondary Ion Mass Spectroscopy (SIMS), Auger Electron Spectroscopy (AES) and Transmission Electron Microscopy (TEM). |

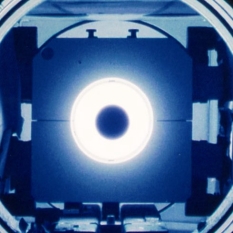

Coating Formation by Sputtering

Fig.1: The production of metallic coatings by sputtering from a post magnetron allows the deposition of films with a high thickness uniformity on the inner surface of a cylinder. |

Contact: C. Eisenmenger-Sittner |